[See image gallery at www.allfordmustangs.com]

It’s a rare occasion when an automaker develops a brand-new engine family. Scarcer still are clean-sheet V8 designs. But bucking modern trends, Ford has created an all-new big-block gasoline unit for use in heavy trucks.

Displacing a burly 7.3-liters, this engine will see service in Dearborn’s Super Duty pickup range as well as its medium-duty vehicles, from the F-250 on up. It will give customers an additional under-hood option, slotting between the base 6.2-liter single-overhead-cam gasoline V8 and Ford’s 6.7-liter Power Stroke diesel.

Capability and outstanding durability were major considerations when creating this new big block. Joel Beltramo, engineering manager for the 7.3-liter engine said, “We have customers that are running four- or five-hundred-thousand miles on our pickup trucks,” and this new V8 has to provide commensurate longevity.

“Classically, when you think about it, many people retire vehicles because the powertrain is worn out. We don’t want that,” explained Beltramo. “And the challenge now is, our aluminum trucks, they’re not going to rust. So, how long will they run? We’re not sure.”

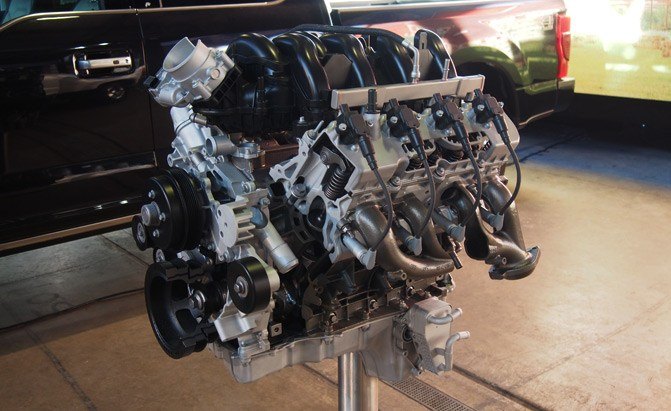

Maximizing durability, engineers went with a tried-and-true pushrod design, one with two (admittedly very large) valves per cylinder. Unlike more modern V8 engines, there’s just one camshaft, nestled in the valley of the engine’s “V.” This sort of design, while arguably outdated on paper, provides numerous benefits in real-world use.

For starters, this engine displaces a husky 7.3-liters, but its exterior dimensions are unusually compact. In comparison, Ford’s 5.0-liter Coyote V8, with its twin-cam cylinder heads and 32 valves looks far wider, making it a tight squeeze in certain engine bays. Aside from trimmer dimensions, going with pushrods also means there are dramatically fewer moving parts, no lengthy timing chains to stretch or complicated phasers to break.

Overhead camshafts and multiple valves per cylinder aid high-rpm airflow, which is great for performance in, say, a Mustang coupe, but this is antithetical to what’s needed in a heavy truck. Low-speed torque and fuel efficiency are much more important attributes.

While Beltramo wouldn’t comment on the operating range of this new 7.3 or even at what rpm peak torque is delivered, he did say, “It’s very capable,” and will run at speeds similar to Ford’s current 6.2-liter V8 and other competing engines.

The overall weight of this powerplant should be very similar to Ford’s 6.2-liter V8, which delivers an advertised 385 horsepower at 5,750 rpm and 430 pound-feet of torque at 3,800 revs per minute. If this new big-block V8 cranks out similar horsepower- and torque-per-liter figures it could be rated at 453 ponies with around 506 pound-feet of twist.

Serving as the foundation of this engine is a rigid cast-iron block. Beltramo said compacted-graphite iron, an ultra-durable material, was not required here as cylinder pressures are relatively low since the engine is naturally aspirated. Within this assembly spins a forged-steel crankshaft supported by four-bolt main-bearing caps further shored up by cross bolts.

Capping the block off is a pair of high-flow cylinder heads made of aluminum to save weight. As for the bore and stroke, Beltramo said they measure 107.2 millimeters (4.22 inches) and 101 millimeters (3.98 inches), respectively.

Gasoline is fed to each cylinder by a port-injection system. This is a simpler and more serviceable solution than competing direct-injection technology, which does have its advantages in certain applications. Simplifying maintenance, the spark plugs, fuel injectors, oil filter and water pump are all easily accessible.

And for all you engine geeks out there (like me!), this big block’s firing order is a familiar 1-5-4-8-6-3-7-2, identical to the 5.0-liter Coyote and even Ford’s very first V8 engine, the venerable flathead that was introduced in 1932.

SEE ALSO: I Drove an 80-Year-Old Car on a 1,000-Mile Road Trip and Lived to Tell the Tale

“If you take that step back, all the knowledge we learned on building turbo-diesels and building our EcoBoost turbocharged engines, all that technology is in here,” said Beltramo, further underscoring the new V8’s durability. “It has to be as tough as we can make it. And so, you will find… some details in here that you wouldn’t expect to find in a naturally aspirated engine.” He said the piston rings feature a special coating, something normally used in turbocharged applications, plus the valves and their seats are made of similarly upgraded metals. “We’re doing it here just to drive the durability as far as we can with the latest technologies for materials.”

There are numerous other details of note on the new 7.3. Piston-cooling jets keep temperatures under control and ensure cylinder walls are always well lubricated. Both a two-stage oil pump and variable camshaft timing improve performance and efficiency. Further cutting parasitic friction are standard roller lifters and rocker arms that run on needle bearings. Certain vehicles will be fitted with ultra-durable cast stainless steel exhaust manifolds designed to withstand the worst abuse customers can dish out.

Aside from longevity, fuel economy is also critical to fleet customers that will be using this new engine extensively. Beltramo said, “This thing was optimized very, very well.” There’s a reason it displaces 7.3-liters and not more or less. It’s designed to run a stoichiometric air-fuel mixture, “That means the perfect amount of fuel to the amount of air you’re taking in,” he explained. “This engine is sized to run that way when it’s pulling heavy loads to maximize fuel economy in the real world.”

With its narrow valve covers and curving exhaust manifolds the new 7.3 resembles Ford V8 engines from years gone by. If you squint, it kind of looks like an FE family engine or maybe something from the 385 series.

Even though this 21st century big block smacks of older blue-oval powerplants, it’s a clean-sheet, from-scratch design. Still, they did keep an eye on the past during development. “We had some old-timers still around that remembered some of those [pushrod] engines and we actually made a point to seek them out and talk to them about what their experiences were,” Beltramo recounted. “Many things we were counseled to avoid,” he added, laughing out loud. They tried to draw on what he called “the human experience” to improve real-world usability of this engine and not just rely on computer modeling and simulation. An example of this is the oil passages for the camshaft bearings. He said they’ve been engineered in such a way that dirt and debris does not get trapped in them, something that improves serviceability years and years down the road.

This new 7.3-liter big-block V8 should deliver commendable performance when it launches late this year, especially when bolted to the company’s new heavy-duty 10-speed transmission. With a focus on durability, it should serve customers well for decades to come. “It’s using all of Ford’s experience with the commercial trucks and the Super Duties,” said Beltramo. “We engineered it from scratch to be the optimum answer for the future.”

a version of this article first appeared on AutoGuide

The post Ford Building New Big-Block V8 for Heavy Trucks: Here’s a Deep Dive for Engine Nerds appeared first on AllFordMustangs.